SecuredGrateTm MOLDED GRATING

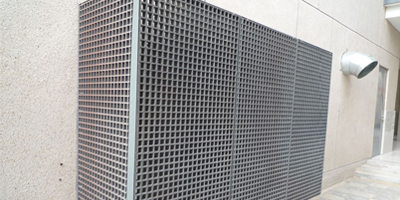

Mona Composites SecureGrateTM Molded Grating panels are manufactured by systematically setting layers of liquid resin and continuous fiberglass roving in a mold. The finished panels are released from the molds after they are cured for a predetermined time. The one-piece interwoven mesh construction of molded grating results in a product with optimal corrosion resistance and bidirectional strength. The grating is “cast” in one piece and there are no mechanical joints between bearing bars. The high percentage of resin (65%) in molded grating also adds to its superior corrosion and optimal impact resistance. The bi-directional trait of Square Mesh Molded gratings offers increased load capacity and panel utilization. These advantages make molded grating a better alternative to steel and aluminum grating products. Penetrations for piping, valve access, and columns can be made without the need for additional structural framing. As molded grating panels are constructed as one piece, penetrations do not affect the structural integrity of the panel and the load is evenly distributed throughout the section and around cut-outs. This differs from pultruded grating products which may require additional supports around penetrations.

Benefits:

- Optimum Corrosion Resistance

- Bidirectional Strength

- High Impact Resistance

- UV Resistance

- Anti-Skid

- Fire-Retardant

- Non-Conductive

- Electronically Transparent

- Minimal Maintenance

- Ease of Fabrication