STRUCTURAL SHAPES

>

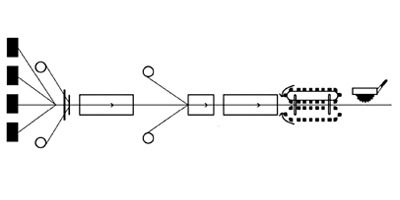

The pultrusion process descibed in earlier pages is suited to manufacturing structural shapes. It allows structural member

to be manufactured to length; the only restriction is transportation limitations.

Continuous glass fibers that enter the process on the left are actually pulled by a tractor (illustrated) or hand-overhand

pullers shown above on the right. The glass bundle of continuous strands is then wrapped with continuous strand mats

that provide the transverse strength. The entire reinforcement bundle is pulled into a liquid resin bath (polyester or

vinyl ester) and wetted out. After that, the wetted reinforcement package is wrapped in a surfacing veil. That leaves a

resin-rich finish on the part and creates both a barrier to corrosion and a smooth finish. The completed package goes

into a prefomer that roughly shapes the package before it enters the heated die for curing. The die is the exact shape

of the final part desired. When the package leaves the die it is over 90% cured and solid. The length of the part

required is pulled through the cutoff saw and the process is complete

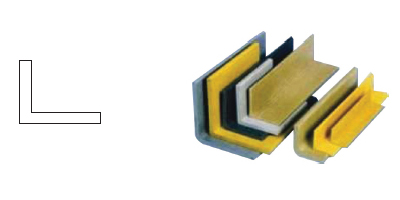

STRUCTURAL SHAPES

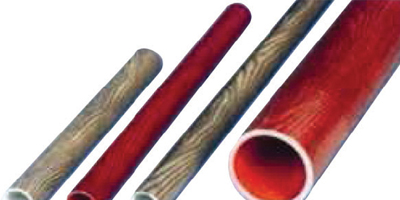

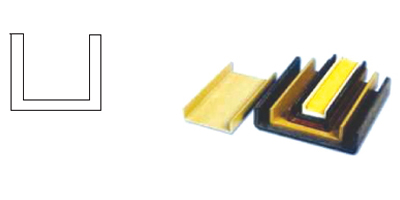

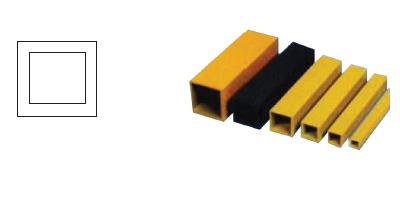

Mona Composites manufactures all standard shapes used for structural projects. They are manufactured in both vinyl ester (standard color is beige) and polyester (standard color is dark gray). Embedment angles are only manufactured in vinyl ester and standard color is dark gray to compliment the color of concrete. Reference Available Shapes List on the following page for a complete list of available structural.